Sunfixings Ground Mounts

GROUND MOUNTED MOUNTING SYSTEMS

Ground-mounted solar panel mounting systems offer a versatile and secure way to install solar panels on the ground. Unlike rooftop systems, ground-mounted systems aren't limited by the size, shape, or orientation of your roof.

📋 For a no-obligation quote on any of these mounts, scroll down for the contact form 👇

We'll usually get in touch on the same business day, or within 24 hours.

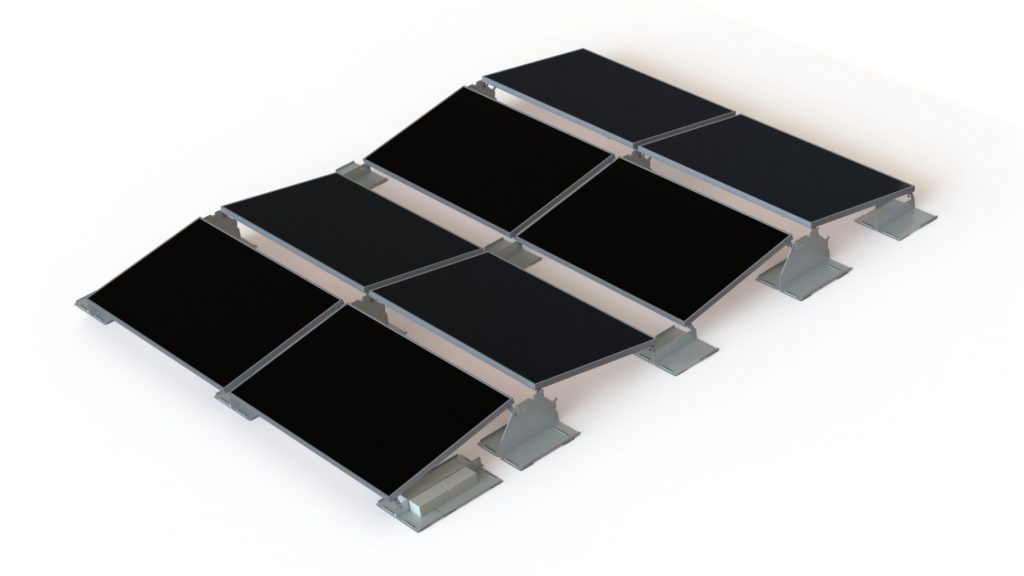

EAST WEST TEGRA

Optimizing Panel Placement with an East-West Split

With this system we can create an east west split for the solar panels, which reduces the space required between the rows of solar panels and in some cases, allow more solar panels to fit on the roof compared to its Light Tegra counterpart.

We lower the ballast, not the quality.

We’ve incorporated aerodynamic principles into the design so that the system uses the effects of the wind uplift to create suction against the roof, which in turn, dramatically reduces the amount of additional ballast.

No heavy point points.

We’ve specifically designed the support feet to be wide enough to distribute the weight of the system over a greater area, so there aren’t any heavy point loads.

We protect the existing roof.

We apply a separation layer to the underside of each and every support foot prior to delivery so that it’s ready to be used with the reassurance that it will protect the existing roofing material.

We even supply the system with the ballast.

We understand that with the expense of lifting equipment and the time constraints involved that sometimes it’s better if the mounting system arrives to your site complete with ballast. Not only does this save you time waiting for more than one delivery, it also removes the hassle of you trying to locate the right amount of ballast for your project.

We follow European Standards and lead by example.

We calculate all projects using a combination of Eurocode Standards, National Standards and physical wind tunnel testing results, safely ensuring the correct amount of ballast is installed.

Doesn't obstruct rainwater.

All flat roofs have some form of a pitch to comply with regulations that require rainwater to flow freely into the guttering system. We’ve ensured that our system also complies with these regulations by designing the support feet so that the rainwater flows around them, as opposed to railed systems that can obstruct the water flow.

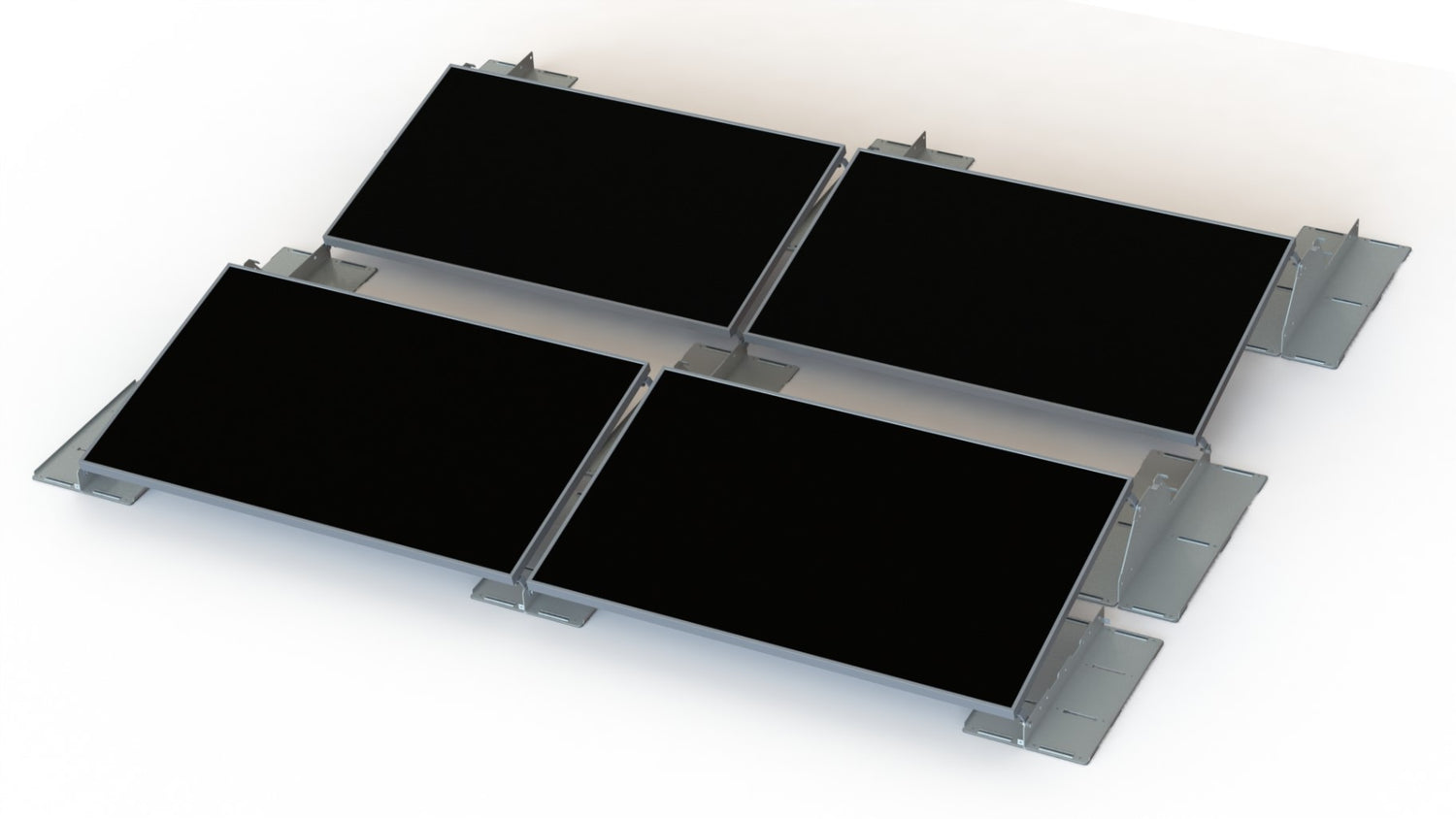

ELEVATION BALLAST

Elevation ballast is a mounting system specifically designed for installing solar panels on flat roofs without penetrating the roof membrane

Added security.

We add wind bracing supports to the back of the elevation frames at certain intervals along the solar panel row to provide added stability against lateral movement. We calculate where you need to place these wind bracing supports and they will be marked them on the drawing layouts that we provide you at point of order.

Module Clamp XL.

Sunfixings Clamp XL fully assembled, Silver Mill Finish and Black Anodised are suitable for 32mm, 35mm, 40mm PV Module Thickness. For PV Module thickness beyond this range, Sunfixings offer alternative and complete Middle and End Clamp Mounting Solutions.

It’s about saving you time without skimping on the quality.

So we’ve pre-assembled all the smaller components, so they’re ready to be simply slotted into the mounting rail profile.

Connect straight to the ballast.

The elevation frames fix directly into the ballast using either stainless steel screws specially designed for fixing into concrete or chemical anchors. The ideal ballast to use for this system is either concrete blocks or lintels with a minimum 100mm depth.

Reach the optimum solar panel angle.

We design and produce the elevated frames locally in the UK, so this gives us the flexibility to be able to incorporate any angle or height requirements that are necessary for your project’s realisation.

Saving you on material and installation time.

Each type of mounting rail that we offer has a different spanning capability according to its size and profile. We use this information in conjunction with other calculations to specify the most suitable mounting rail profile from our collection. This means that we optimise the distance between the elevated frames, which in turn, saves you on material and also installation time.

Choosing the right solar panel orientation.

This system can easily accommodate solar panels in either landscape or portrait orientation. For the portrait option, we produce an elevation with 4 sides to allow the solar panel to be clamped in its quarter zones and to help reduce the amount of unnecessary material. A simple triangle is produced for a landscape option, which also allows the solar panel to be clamped in its quarter zones along its length.

LIGHT TEGRA

The Light Tegra is a low-ballast mounting system designed specifically for flat roofs .

Designed simplicity without compromising the strength.

We’ve taken great care in designing a system that is really quick and simple to install but also requires a minimal amount of ballast. The design incorporates aerodynamic principles, which allow the system to use the effects of the wind uplift to its benefit and effectively self-ballasts.

We protect the existing roof.

We’ve taken significant steps to ensure that our system complies and protects the existing roof covering by applying a separation layer to the bottom of the support feet prior to delivery. The support feet are also slightly curved around the edges to avoid any sharp edges, so that they don’t damage the existing roof covering.

We lower the ballast, not the quality.

We’ve incorporated aerodynamic principles into the design so that the system used the effects of the wind uplift to create suction against the roof, which in turn, dramatically reduces the amount of additional ballast.

We even supply the system with the ballast.

We understand that with the expense of lifting equipment and the time constraints involved that sometimes it’s better if the mounting system arrives to your site complete with ballast. Not only does this save you time waiting for more than one delivery, it also removes the hassle of you trying to locate the right amount of ballast for your project.

No heavy point loads.

Since we’ve designed the system to be low ballast, we’ve made sure that the robust support feet are wide enough to avoid any heavy point loading.

We follow European Standards and lead by example.

We calculate all project using a combination of Eurocode Standards, National Standards and physical wind tunnel testing results, safely ensuring the correct amount of ballast is installed.

It doesn't obstruct rainwater.

All flat roofs have some form of a pitch to comply with regulations that require rainwater to flow freely into the guttering system. We’ve ensured that our system also complies with these regulations by designing the support feet so that the rainwater flows around them, as opposed to railed systems that can obstruct the water flow.

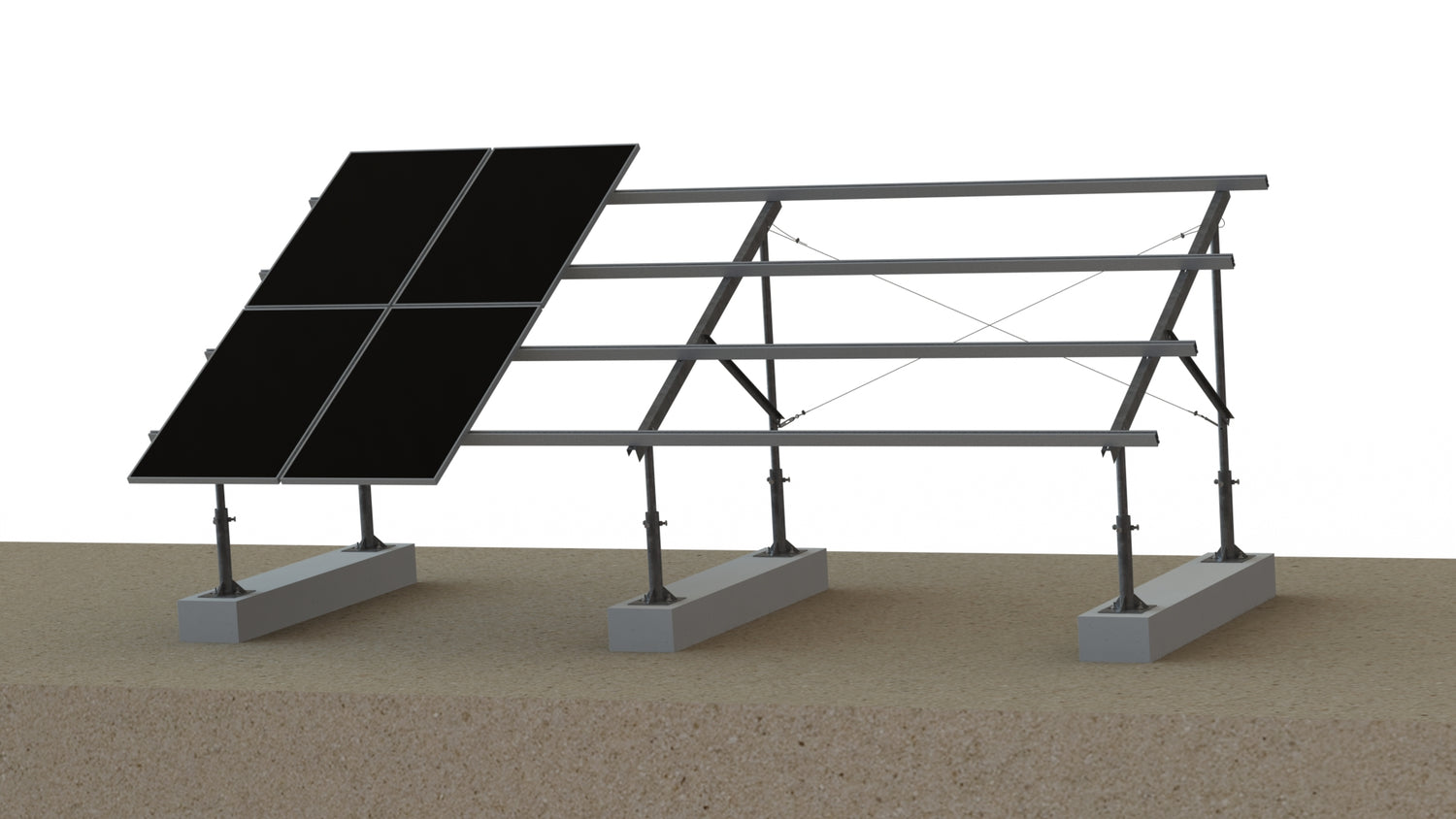

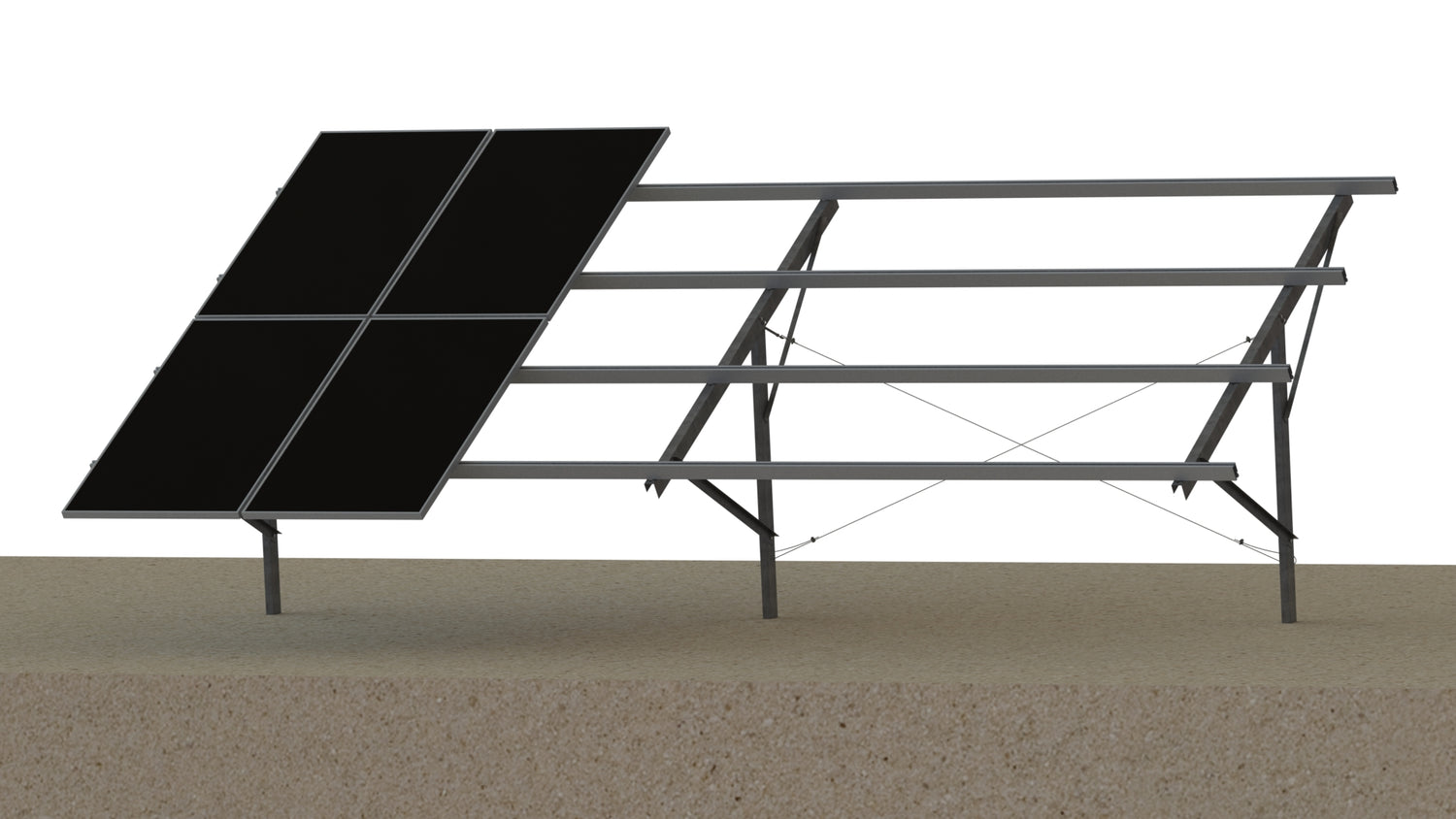

PARK TEGRA BALLAST

The Park Tegra Ballast is a ground-mounted solar panel mounting system designed for situations where traditional ground screw solutions aren't ideal.

Connects straight to ballast.

We’ve designed the support feet that sit beneath the main structure, to fix directly into concrete ballast using chemical anchors. There are 2 main fixings per support foot, which provides a secure hold into the concrete foundation.

Although this is the main method of connecting to ballast, there is an alternative whereby a concrete mixture is poured around the support feet to create a secure hold.

These foundations can be dug into the ground with a layer of soil applied over the top to hide them from view, or can simply be left to sit on top of the existing ground.

Ideal for hard ground types.

This solution is perfect for ground conditions that make it difficult or impossible to either screw or drive other systems into place. Instead, the frames are securely connected to concrete ballast to weigh it down against the wind forces acting on the system.

Make the use of the land around us.

The benefits of ground mounted solutions over roof mounted options, include the ability to set the solar panels at the optimum orientation and angle in order to maximise the system’s energy generation. They can also make use of land that is otherwise left empty, such as, fallow land, brownfield sites and even landfill sites. They offer easy access to the array and allow regular maintenance without the need for any specialist lifting equipment.

Holds 2 solar panels in portrait.

Our standard structure is designed to support 2 solar panels high in the portrait orientation, as this allows more space within the array for more solar panels. There isn’t a limit to how many solar panels can be installed in a single line.

Universal. Adjustable. Flexible.

We know that sometimes ground conditions can be problematic, whether it’s because of a slight incline or just the simple fact of the land not being even. To get around this, we’ve ensured that our Ground Anchor system allows greater adjustability in the height of the individual posts of the frame, as well as the positioning of the posts within the Ground Anchors. The framing is designed to work with most solar panels, allowing it to universally suit most projects and with no limit to how long you can make the array, it allows you to make the most of the space available.

Added security.

We add wind bracing in the form of tension cable to the back of the frames at certain intervals along the solar panel row, to provide added stability against lateral movement. We calculate where you need to place these wind bracing sets and they’ll be marked on the drawing layouts that we provide you at the point of order.

Off the shelf, delivered straight to you.

Our standard product allows the solar panels to be mounted in a portrait orientation, which we carry in stock and can often facilitate a next day delivery service straight to your site (subject to availability and delivery location). This module orientation allows more solar panels to be installed on the land allocated, however, if a landscape option is preferred, we can create a bespoke frame for your project.

We're using resilient materials, because we've designed it to last.

We favour the hot-dipped method of galvanising the steel elements of our ground mounted systems. This is because, compared to electro-galvanising, it allows us to specify the thickness of the protective coating. The average thickness of steel parts in other industries is around 200g/m, but at Sunfixings we double this, so that this protective coat is a minimum of 400g/m and therefore, ensuring a long lasting life for our systems.

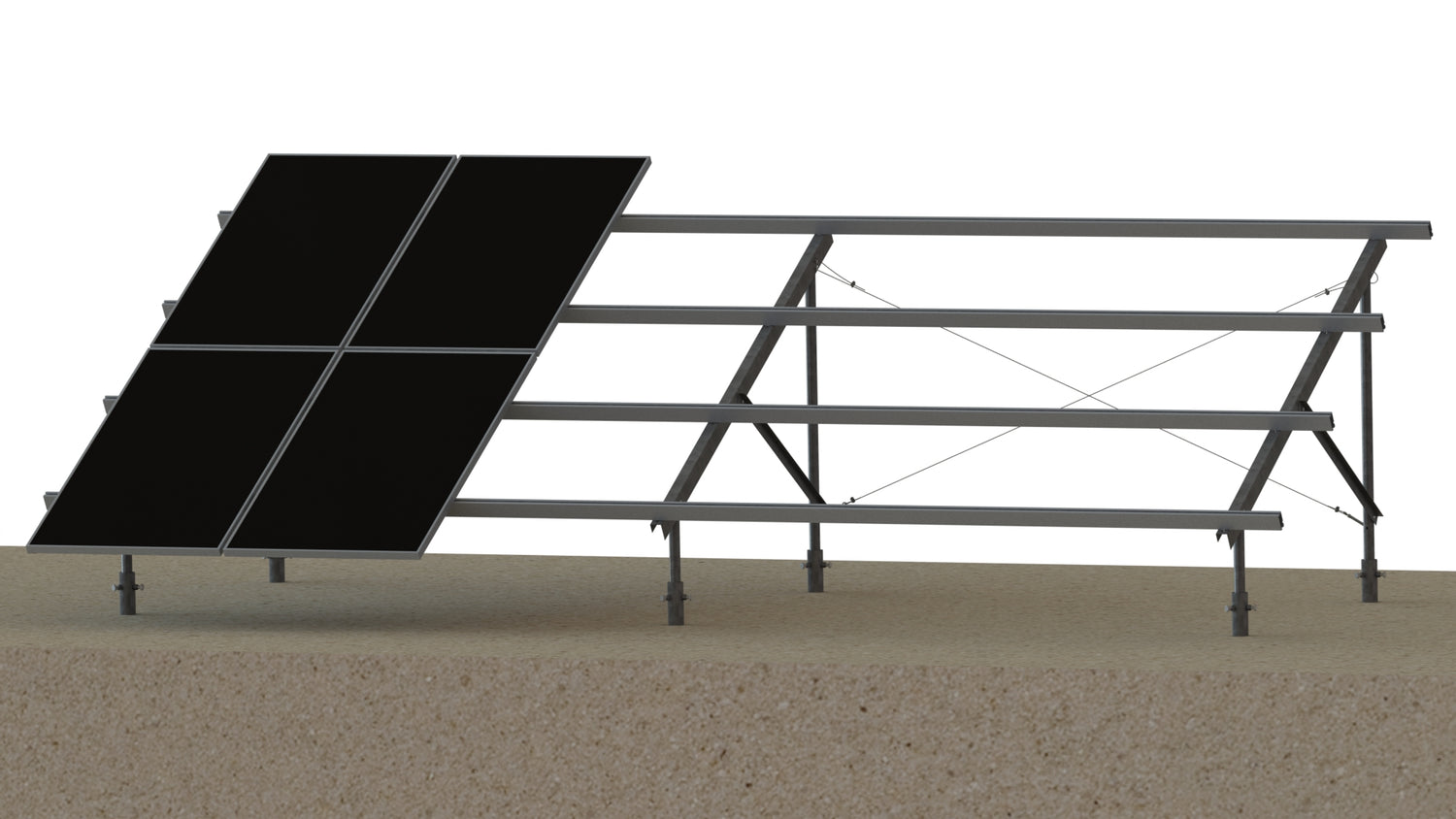

PARK TEGRA GROUND ANCHOR

The Park Tegra Ground Anchor is a ground-mounted solar panel mounting system designed for fast and efficient installation on suitable ground conditions .

Screws into the ground.

This system is designed to easily screw into the ground that has a high clay content, making it a fast and popular solution, particularly for small to medium sized projects.

Universal. Adjustable. Flexible.

We know that sometimes ground conditions can be problematic, whether it’s because of a slight incline or just the simple fact of the land not being even. To get around this, we’ve ensured that our Ground Anchor system allows greater adjustability in the height of the individual posts of the frame, as well as the positioning of the posts within the Ground Anchors.

The framing is designed to work with most solar panels, allowing it to universally suit most projects and with no limit to how long you can make the array, it allows you to make the most of the space available.

Holds 2 solar panels high in portrait.

Our standard structure is designed to support 2 solar panels high in the portrait orientation, as this allows more space within the array for more solar panels. There isn’t a limit to how many solar panels that can be installed in a single line.

Mind the thermal gap.

Our mounting rail profiles are produced from high quality aluminium, which contracts during colder weather and expands during warmer weather. While this expansion is less than a couple of millimeters a year, it’s important to leave regular gaps to allow this natural process occur.

This is why we have a separate component called the Flexible Connector, which fixes into one side of the mounting rail and controls this expansion without compromising the length of the overall array.

Not all systems have to leave their mark.

It’s important for us that, as a sustainable energy solution, our system settles within its surrounding environment. This is why we’ve ensured it creates minimal ground disturbance and can be incorporated into land which holds livestock.

Additional security.

We add wind bracing in the form of tension cable to the back of the frames at certain intervals along the solar panel row, to provide added stability against lateral movement. We calculate where you need to place these wind bracing sets and they’ll be marked on the drawing layouts that we provide you at the point of order.

Recommended equipment.

We recommend hiring a 2.5 tonne cylinder head hydraulic auger unit, with a reverse option for installing the Ground Anchors. Sometimes the ground may need a little more pressure applying to it and for this a 4-5 tonne auger unit is better suited. We’ll lend you an auger adapter that fits the auger unit to help screw them in.

We'll produce bespoke structures to support solar panels mounted in landscape.

While our standard stock is catered for mounting solar panels in portrait, we can produce bespoke frames to allow the mounting of the solar panels in landscape.

PARK TEGRA PILE DRIVEN

The Park Tegra Pile Driven system offers a robust ground-mounted solution for solar panels, utilizing a method similar to traditional pile driving techniques used in construction .

It's driven into the ground.

Using traditional piling techniques used through the construction industry, this system has a single leg that is driven into the ground to achieve a secure anchoring point, making it a quick, streamlined installation method for medium to large projects.

Purpose designed.

The single leg has been specifically designed and verified by our independent structural engineer for the purpose of piling, unlike similar systems available on the market, which use purlins that are designed to be used within roofing construction.

Saving you on material and installation time.

Each type of mounting rail that we offer has a different spanning capability according to its size and profile. We use this information in conjunction with other calculations and information about the ground quality to specify the most suitable mounting rail profile from our collection.

This means that we optimise the distance between the pile driven structures, which in turn, saves you on material and also installation time.

Holds 2 solar panels high in portrait.

Our standard structure is designed to support 2 solar panels high in the portrait orientation, as this allows more space within the array for more solar panels. There isn’t a limit to how many solar panels can be installed in a single line.

Not all systems have to leave their mark.

It’s important for us that, as a sustainable energy solution, our system settles within its surrounding environment. This is why we’ve ensured it creates minimal ground disturbance and can be incorporated into land which holds livestock.

Additional security.

We add wind bracing in the form of tension cable to the back of the pile driven structures at certain intervals along the solar panel row, to provide added stability against lateral movement. We calculate where you need to place these wind bracing sets and they will be marked on the drawing layouts that we provide you at point of order.

We're using resilient materials, because we've designed it to last.

We favour the hot-dipped method of galvanising the steel elements of our ground mounted systems. This is because, compared to electro-galvanising, it allows us to specify the thickness of the protective coating. The average thickness of steel parts in other industries is around 200g/m, but at Sunfixings we double this, so that this protective coat is a minimum of 400g/m and therefore, ensuring a long lasting life for our systems.

Module Clamp XL.

Sunfixings Clamp XL fully assembled, Silver Mill Finish and Black Anodised are suitable for 32mm, 35mm, 40mm PV Module Thickness. For PV Module thickness beyond this range, Sunfixings offer alternative and complete Middle and End Clamp Mounting Solutions.

PARK TEGRA SINGLE STRUCTURE

The Park Tegra Single Structure offers a versatile and adaptable ground-mounted solution for solar panels, catering to a variety of project needs .

1 solar panel high.

Sometimes a ground mounted system is required to sit lower to the ground and reduce its overall height, whether this is because of aesthetic or planning permissions reasons. So we’ve taken some elements from our other system to create an elevated frame suitable for holding a single solar panel high. This allows us to easily adjust the height and angle of them.

It can either screw into the ground.

We’ve specifically designed the connection of this frame to be as universal as possible, in order to suit a variety of different situations.

This system can easily be screwed into ground that has a high clay content using our Ground Anchors. They connect to the elevated frame via a T shaped adapter. There’s a layer of UV resistant EPDM applied to this in, in order to separate its galvanised steel material from the aluminium elevated frame to avoid any chemical reaction from occurring.

Easy to install.

We recommend hiring a 2.5 tonne cylinder head hydraulic auger unit, with a reverse option for installing the Ground Anchors. Sometimes the ground may need a little more pressure applying to it and for this, a 4-5 tonne auger unit is better suited. We’ll lend you an auger adapter that fits the auger unit to help screw them in.

It can connect to concrete ballast.

For instances where the ground is too hard to screw into, a different set of support feet can be used, which allow the system to fix into concrete ballast with chemical anchors. The ballast can be poured into a ditch and then covered with a layer of top soil to hide it from view, or it can use pre-cast concrete blocks that are simply put directly on top of the ground. Either way, we can advise you on the exact weight and dimensions that you need for your project to withstand the wind forces in that location.

Enjoy the freedom to define the height of the system.

We locally produce the elevated frames in the UK, which allows us to tailor them to any specification. So whether you need 900mm or 200mm between the solar panel and the ground level, we can incorporate this, together with any angle required, to suit your individual project.

We're using resilient materials, because we've designed it to last.

We favour the hot-dipped method of galvanising the steel elements of our ground mounted systems. This is because, compared to electro-galvanising, it allows us to specify the thickness of the protective coating. The average thickness of steel parts in other industries is around 200g/m, but at Sunfixings we double this, so that this protective coat is a minimum of 400g/m and therefore, ensuring a long lasting life for our systems.

It's about saving you time without skimping on the quality.

So we’ve pre-assembled the smaller components, such as the Fixed Connectors, which connect the lengths of mounting rail together, so that they’re ready to be simply slotted into the mounting rail profile.

Module Clamp XL.

Sunfixings Clamp XL fully assembled, Silver Mill Finish and Black Anodised are suitable for 32mm, 35mm, 40mm PV Module Thickness. For PV Module thickness beyond this range, Sunfixings offer alternative and complete Middle and End Clamp Mounting Solutions.